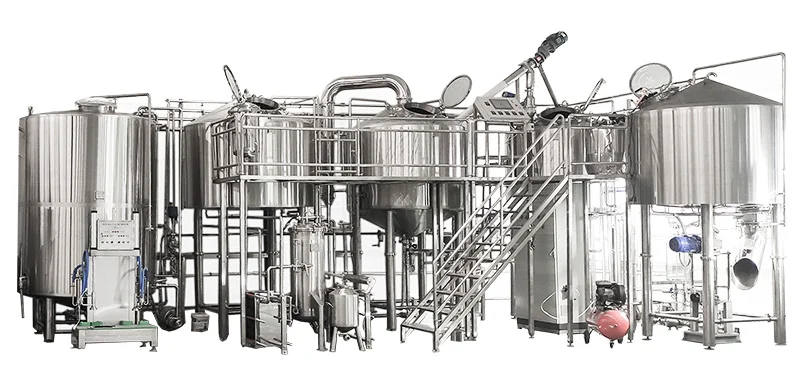

2000L Three-Vessel Brewhouse

Overview

The 2000L Three-Vessel Brewhouse is engineered for high-capacity, professional beer production. With fully independent Mash Tun, Lauter Tun, and Kettle/Whirlpool Tank, this advanced brewing system empowers commercial breweries to scale up with precision, speed, and consistency.

Whether you’re entering large-scale distribution, packaging in bottles/cans, or brewing multiple SKUs daily, this system delivers repeatable results, seamless automation, and industrial reliability.

2000L Three-Vessel Brewhouse | Cost-Effective Brewing System for Expanding Breweries

Introduction

The 2000L three-vessel brewhouse is designed for breweries aiming to expand production capacity while keeping equipment investment at a reasonable level. With a batch size of 2000 liters (20HL), it allows craft breweries and microbreweries to reach higher output volumes without compromising flexibility or beer quality.

The system includes a mash/lauter tun, a brew kettle, and a whirlpool, combining practicality with brewing efficiency. It is an ideal solution for breweries that require larger batches but still want to maintain a wide variety of beer recipes.

Technical Parameters

| Specification | Details |

|---|---|

| Capacity | 2000L (20HL) per batch |

| Vessel Configuration | Three vessels: Mash/lauter tun, Brew kettle, Whirlpool |

| Material | Stainless Steel 304 / 316 |

| Heating Methods | Steam, Direct Fire, or Electric |

| Control Options | Manual, Semi-automatic, PLC touchscreen |

| Cleaning System | Built-in CIP spray balls |

| Daily Brewing Capacity | 2000L – 8000L (1–4 brews per day) |

| Applications | Microbreweries, Brewpubs, Regional craft beer production |

| Certifications | CE / ISO9001 |

Advantages of the 2000L Three-Vessel Brewhouse

Large-Scale Production – Perfect for breweries preparing to expand into wholesale distribution or increase daily output.

Balanced Cost and Efficiency – Compared to four-vessel setups, the three-vessel system reduces investment while maintaining high brewing performance.

Versatile Brewing Capability – Suitable for brewing both traditional lagers and specialty craft beers in consistent quality.

User-Friendly Operation – Designed for easy handling, cleaning, and process monitoring with advanced automation options.

Future Expandability – Easily paired with additional fermentation tanks, brite beer tanks, and packaging lines.

Application Scenarios

The 2000L brewing system is widely used in:

Regional breweries aiming to expand sales in restaurants, pubs, and supermarkets.

Large brewpubs serving high customer volumes daily.

Contract brewing facilities producing beers for multiple brands.

Export-oriented breweries requiring CE-certified equipment to meet international standards.

Case Studies

Germany: A brewery upgraded from a 1000L brewhouse to our 2000L three-vessel system, doubling production and entering retail distribution channels.

Netherlands: A brewpub installed the system to brew seasonal specialties alongside their flagship beers, achieving consistent high output with reduced operating costs.

These real-world cases prove the 2000L three-vessel brewhouse is a reliable choice for breweries entering the next stage of growth.

Certifications & Support

All our 2000L brewery systems are CE and ISO9001 certified. We ensure every brewhouse is tested before shipping and provide global technical assistance.

Our service includes:

Equipment layout planning

Customized tank design

Installation guidance & operator training

Lifetime after-sales support

Frequently Asked Questions

Q: How does the three-vessel system compare to a four-vessel setup?

A: The three-vessel brewhouse offers a lower entry cost, while still providing efficient wort production. Four-vessel systems are better suited for very high-volume breweries.

Q: How much space is required?

A: Around 100–150 square meters, depending on configuration and additional tanks.

Q: What is the maximum daily production?

A: Up to 8,000 liters, depending on brewing schedule and fermentation capacity.

Q: Can this system be automated?

A: Yes, we provide manual, semi-automatic, and fully automated PLC control options.